MENU

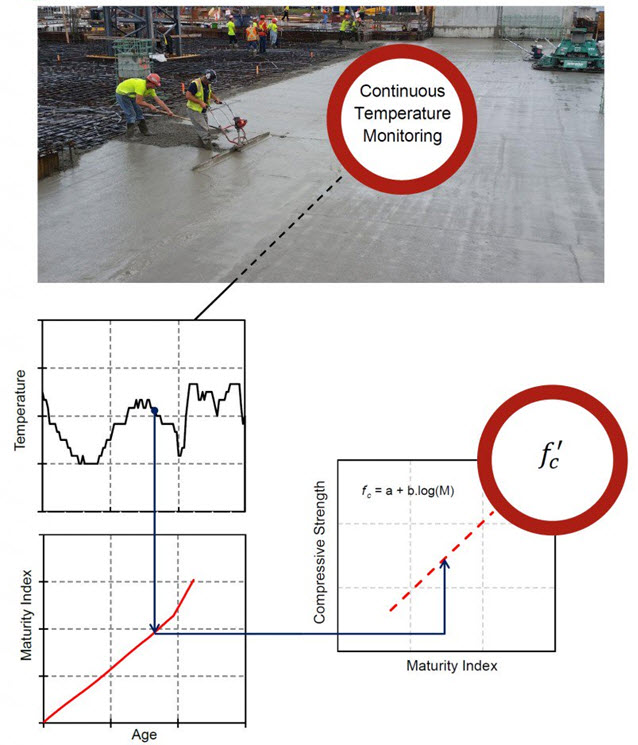

Concrete maturity indicates how far curing has progressed. Maturity is the relationship between concrete temperature, time, and strength gain. It is represented by an index value that can be measured in real time in the field.

The maturity method, often simply referred to as maturity, is a way of evaluating new concrete’s in-place strength by relating time and temperature measurements to actual strength values.

To expedite schedules, increase safety, and improve construction methods, construction teams want to know the strength of their concrete at the job site in real time. Since maturity is related to concrete strength, the maturity method is a way to accomplish this without solely relying on standard test specimens and laboratory testing.

Maturity is calculated by tracking changes in fresh concrete temperature over time. Since each concrete mix has its own strength-maturity relationship, we can use maturity to estimate the strength of that mix at any moment after placement. When we know the maturity of a certain concrete, we can use that concrete’s specific strength-maturity relationship.When using the maturity method, construction teams can estimate real-time strength gain of in-place concrete on the job site. There’s no need to waste valuable construction time waiting for the strength of standard test specimens to catch up to the in-place concrete.

Basic Steps

When using the maturity method, construction teams can estimate real-time strength gain of in-place concrete on the job site. There’s no need to waste valuable construction time waiting for the strength of standard test specimens to catch up to the in-place concrete.

Without maturity monitoring, in-place concrete strength is estimated by performing compressive cylinder tests in a laboratory. Relying solely on lab tests requires several specimens and can waste valuable time if a project’s in-place concrete reaches sufficient strength before standard test intervals. In the construction business, time is money.

To save time and money on a project, the construction team monitors maturity to quickly determine when concrete has reached its required strength.

Key Maturity Benefits

Mass Concrete Temperature Monitoring

Mass Concrete temperature monitoring is the action of recording and reading the temperature of freshly poured mass concrete elements. This requires a concrete temperature sensor to be placed near the center of the element.

In order to ensure the quality and durability of larger projects, it is important to monitor and control concrete mix temperature, ambient temperature, and differential temperature in mass concrete elements. Temperature differences can cause stress that leads to thermal cracks, as well as loss of structural integrity, thus shortening the life and decreasing the strength of the mass concrete element. If the temperature goes below a certain number, the hydration of water can slow or stop meaning the concrete won’t set properly and won’t achieve optimal strength. When temperatures are properly monitored, it allows for appropriate adjustments to be made when needed.

The initial process for temperature monitoring of concrete mixtures is based on predictions made by taking into account the design of the concrete mix, the shape of the project, the ambient temperature, and more. Once the concrete is in place, temperature monitoring sensors and devices are used to report on changing temperatures.

Microedge’s thermocouple data loggers have been used in many construction sites for concrete temperature monitoring purpose. LPTM-1 data logger can accommodate seven thermocouple channels and the 10-year battery life will ensure the data won’t be accidently lost. Its 8-MB flash memory can store years of data. PL-TW is another thermocouple data logger with WIFI feature. It has eight thermocouple channels and the data can be transferred to the office via wireless Ethernet.

SiteView software can monitor the temperature changes in real-time mode as well as download the data and display the chart.