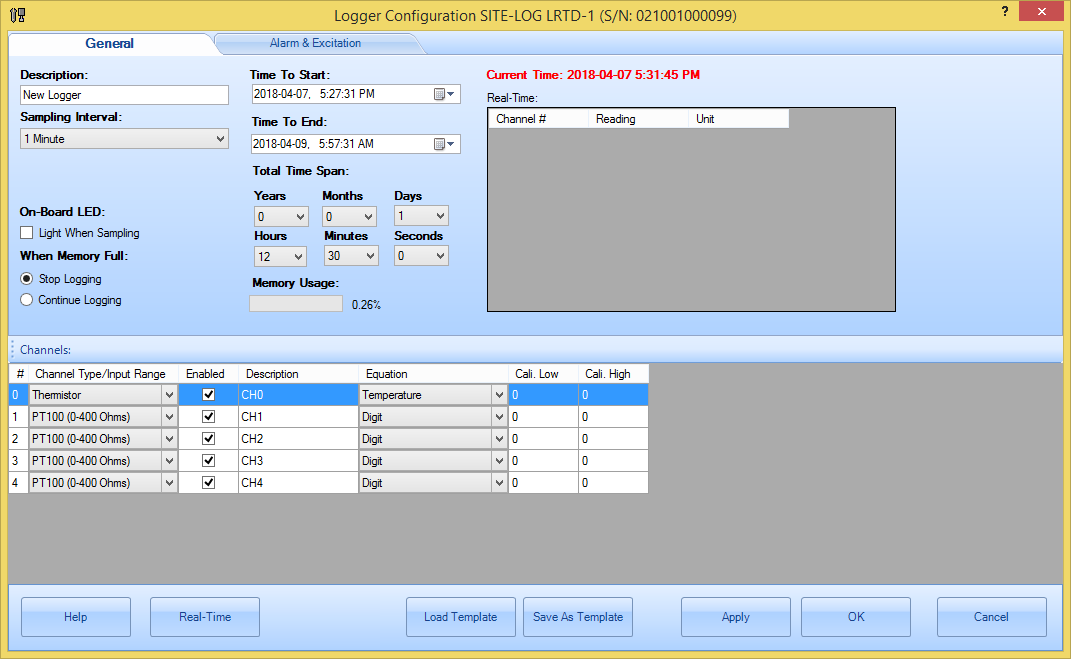

Configuration of the logger is the

procedure to change the properties of the logger and start a new session of

logging. If you are already in the Logger

Status page, clicking on the Configure button will bring up the Logger

Configuration dialog: The new session can be started immediately after the logger

is configured or start in the future by adjusting the Time to Start

field. If you want the logger to stop logging after a specific

period of time: If you want the logger to continue logging for a specific

period of time: If the start time is unknown and you want to activate the new

session in the field: When the logger is operating, the

logger samples the source channels in a preset time

interval (sampling interval). Most of Site-Log loggers can run as fast as

sampling one channel every 20 milliseconds, or as slow

as sampling all channels every 12 hours. If the sampling interval is

set 5 seconds or bigger, the logger will operate in normal sampling mode.

In this mode, if the logger is logging data, the logger will continue operating

while it is communicating with the host device. If the sampling

interval is set below 5 seconds the logger will operate in fast sampling

mode. In this mode, the logger needs

the external power supply for the logging period and the communications with the

logger will force the logger to stop logging. The above example is for SITE-LOG

series. For iLog series, you can decide either below 5

seconds or 1 second the logger will run in fast mode. For PRECISE-LOG series,

there is no fast mode and the fastest interval is 1 second. When the logger is operating, the

logger measures the input of each ENABLED channel. Be sure to enable the

channel if you want the channel be recorded. If one channel’s measurement

relies on other channels’ measurements (A custom equation may use other

channels’ measurements for the current channel’s calculation), be sure to enable

those dependent channels. Some of the Site-Log loggers are

featured with software programmable channels. The input range of those channels

can be changed via SiteView. When the range is changed

to better fit the actual input signal’s range, better resolution and accuracy

can be obtained. For instance, changing the Input Range of a programmable voltage

channel to 0 – 2 V will get better resolution if you know the input source’s

range will be within 0 – 2 V. When the logger saves the data the

logger saves the data in digital format. SiteView

converts the digital values to the physical measurements after the data is

downloaded to the computer. double

output; } Starting from SiteView 3, a new factory Liner equation was introduced

and you can fill out four parameters to quickly create a linear equation.

Refer to this video tutorial for the instructions: Although you can go through the procedure in Calibrate

Logger chapter to calibrate a logger, you can also use Logger

Configuration dialog to do a quick calibration for all channels of the

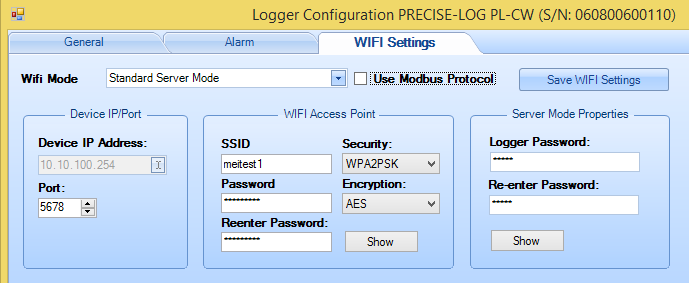

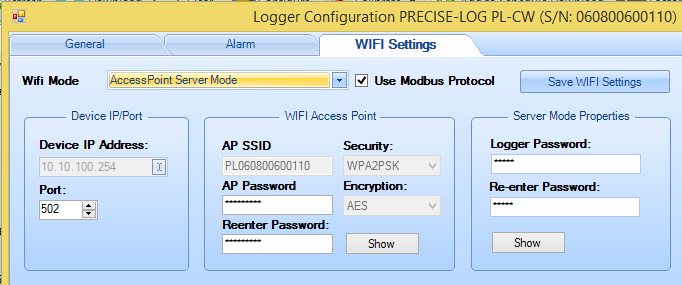

logger. If PRECISE-LOG contains a WIFI

module, the following are used to configure the module. There are two WIFI mode: 1

Standard Server Mode: 2

AccessPoint Server

Mode: In this mode, the data logger

will create a WIFI Access Point for a host PC to join. AP SSID is the AP the data logger

created. The AP name is based the data logger's serial number and it is formated

as "PL" + "logger's serial number". You can change AP password to

join this access point. After you joined you can communicate with the data

logger through USB Server connection. The IP address of the data logger is fixed

to: 10.10.100.254. Once you have finished making changes to the available

settings, you can click OK button to save the settings to the logger. The

logger will start to record data from the Time to Start field you have set. WARNING: By clicking OK or Apply buttons, all

recorded data in the logger will be lost. If the data is important please ALWAYS

download the data before configuring the logger.

Decide when to

start and when to stop logging

If you want the logger to stop at a specific time:

Decide how

often logger samples source

Decide which

channels to log on

Decide how to

convert to physical measurement

SiteView does the data conversions by using equations. An

equation is a software entity handling the conversion from one data format to

another. SiteView contains the built-in equations

for those predefined channel types and the customer-defined equations that can

be applied to all channel types.

A custome-defined equation (custom equation) is a piece of

script (C# source code) in the format of function implementing the data

conversion.

When a channel is configured, an equation is applied to

the channel. After SiteView has retrieved the logger

status SiteView locates the equation entity by the

equation name saved inside the logger. Once the equation entity is identified

the equation entity will handle the data conversion.

This depends on the physical measurement and the input

source parameters. If you are using 0 – 10 VDC channel to record a voltage

source, you can use a built-in equation “VoltageDC”.

If you are recording a 0 – 10 VDC transducer as the source input, and the

transducer has the measurement range of 0 – 5000 PPM CO2, you need to write

your custom equation like this:

public

double

CO2Equation(double

Input)

{

output = 5000 * Input

/ 10 ;

return

output;

The above equation implements the relationship between

the input voltage value and the output physical PPM value. A voltage

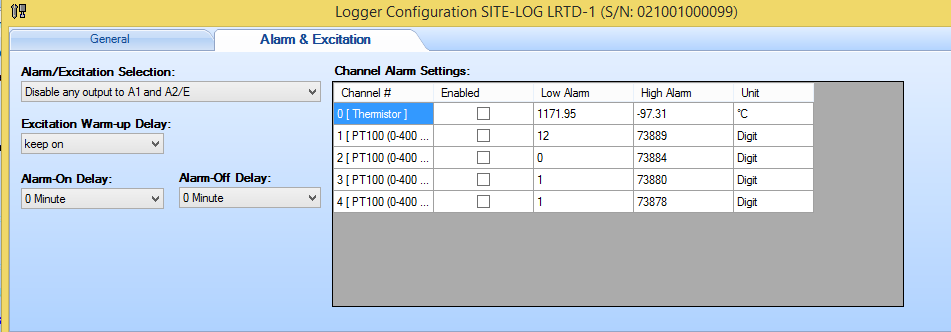

is converted proportionally to a PPM value. Manage Alarm and Excitation

Control (for SITE-LOG series)

When the

logger is recording data, it compares the current reading with Low/High Alarm

values that is previously saved in the logger for each channel. If all the

following conditions are met, the logger will be in Alarm state:

1. The current reading is beyond the Low/High Alarm

values.

2. Alarm is enabled for that channel.

3. Alarm-On Delay’s

counter is counted down to zero.

In the figure illustrated

below, you can check “Alarm Enabled” check-box if you want to enable the Alarm

of the channel. And you can adjust “Low Alarm” and “High Alarm” values so that

when the measurement is below “Low Alarm” or above “High Alarm” it will

trigger the alarm.

If the logger is alarm

state, the logger can energize Alarm1 and/or A2/E terminals in order to

control the external devices like siren auto dialer etc.

At the left side of the above figure, you can change Alarm/Excitation Selection to decide

which terminals the logger will work with when there is an alarm.

Excitation

output is used when you need to save the electric power of the device that

provides the signal source to the data logger. When there is no local power

available and a battery pack is used to power the transducer, excitation

control greatly reduces power consumption by turning on the transducer only

when it samples the data and turning off the transducer after the sampling.

A2/E on the terminal strips can be configured by for excitation

purpose.

In order to enable A2/E,

one of the following Alarm/Excitation Selection must be selected:

Excitation control to A2/E, both high and low

alarm to Alarm1

Excitation control to A2/E, low alarm to

Alarm1

Excitation control to A2/E, high alarm to

Alarm1

Excitation Warm-up Delay is used to specify how much

delay will be set after the excitation terminal is activated and before the

logger is taking the sample. If the measurement source device needs certain

time to stabilize the signal output you may need to set this parameter so the

logger will wait certain time before it takes the sample. Quick way to calibrate logger

These two fields specify the

calibration values that are used for measurement

adjustment.

Cali. Low value specifies the

digital value that is over zero when the input value is the lowest value (for

0 – 5 VDC channel the lowest value is zero volt). For instance, if you apply

zero volt input and the logger measured 100 as the digital value, then

Cali. High value specifies

the digital value that is over 65535 when the input value is the highest value

(for 0 – 5VDC channel the high range is 5 volt). For instance, if you apply 5

volt voltage to the channel and the logger measured 65100 as the digital

value. Then

The valid range for

these two parameters is from –32768 to 32767.

The

following figure illustrates the relationship between an ideal data line and a

measured data line and how

Cali.

Low and

To calibrate a

channel:

1.

Click

Real-Time button to enable Real-Time table. Notice the real-time

readings are updated in Reading cells for all

channels.

2.

Check the

difference between the reading you see and the reading it is supposed to be.

Adjust

3.

If you are

satisfied, click Apply button to save the parameters to the logger or

click OK button to save the parameters and close the dialog.

Save WIFI Related

Settings (for PRECISE-LOG with WIFI series)

In this mode, both the data logger and a host

PC will join an existing WIFI network (Access Point).

Save Settings and Start New

Session